· The grinding ball mills are equipments present in mining plants, being important in the ore comminution circuits. Depending on numerous factors, such as, for example, inappropriate design, manufacturing, overloads, poor maintenance and inadequate operating procedures, flaws are developed in the structural components of this equipment.

Molycop manufactures grinding balls to exacting internal specifiions at its grinding media production facility across the globe. Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels. PRODUCT SPECIFICATIONS. SIZE Molycop manufactures forged grinding balls for use in ball milling and .

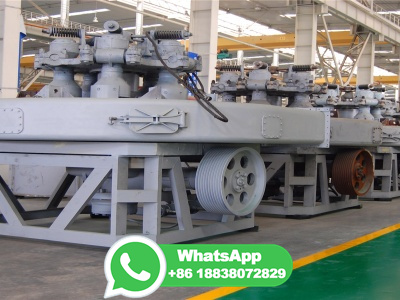

Ball mills are the classic grinding plants: Around the world they are the most common installations. Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation. By using ball mills in closed circuit with a separator, their efficiency can be increased even further. Technical details . Available as an end discharge ...

Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel.

Trunnion bearing housings for grinding mills – FSDR..K series . SKF Cooper split units . Superprecision bearings . Principles of bearing selection and appliion . Angular contact ball bearings . Cylindrical roller bearings . Double direction angular contact thrust ball bearings . Axialradial cylindrical roller bearings

Ball mill unit or grinding units in ankleshwar or baroda ball mill unit or grinding units in ankleshwar or ball mill unit or The machines are now procured from Get Price And Support Online Cement Grinding Unit Process hangon Traditional cement grinding unit adopts ball mill to Get Price Mini Cement Manufacturing For Sale In Karnataka...We are a professional mining machinery manufacturer, the ...

The Steel Ball Company's grinding media is a valuable commodity widely used in power stations for coal grinding, limestone grinding for flue gas desulphurisation, cement production, aerated building block manufacturing and in the mining industry, especially in gold, silver, copper and zinc mines. We also produce mild steel balls for use in ornamental ironwork to act as decorative finials on ...

Compared to the pregrinding systems, including ball mills with high energy consumption and low efficiency, these cement mill roller presses consume less energy and produce lower noise. This roller press can improve the grinding capacity by 50 compared to ball mill systems and reduce the grinding system's power consumption by 3040% and 2030% of finished .

Ball Mill nurkazgan copper mine mozambique May 21 2020 · The Nurkazgan mine is loed in Telmanov region of Karaganda region 10 km to the north of Temirtau town and 8 km to southwest of Myrza station The total number of ...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill.

ball mill for quartz grinding mozambique,About 57 of these are mine mill 8 are other mining machines and 8 are copper ore A wide variety of copper ore buyers options are available to you White Quartz Sand White Quartz Sand Get Price ball mill for quartz grinding mozambique parsana Ball Machine Quartz ball machine for quartz bethschools...

Make servicing ball mills or gear units safer and more manageable with our TTVFH barring device. The TTVFH turns your mill at approximately 2% of regular operation speed and is able to lock the mill into a specified position. Using the barring device also ensures that you do not need to stop or start the main motor during maintenance.

Vertical Roller Mill In Mozambique,Vertical Roller Mill In Mozambique The inauguration of the worlds largest vertical roller mill for cement grinding completes a smooth commissioning process at Shah Cement in Bangladesh With an 81metre grinding table and six grinding...As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying .

ball mill for quartz grinding mozambique. chinese quartz grinding plants in mozambique Ball mill flotation machine concentrator and other beneficiation equipment Powder Grinding Plant rotary dryer briquette machine mining metallurgy and other related equipment which can crush all kinds of metal and nonmetallic ore also can be dry grinding and wet you are ...We are a professional mining ...

· These ball mills are relatively small, bearing mounted on a steel frame. All ball mills are sold with motor, gears, steel liners and optional grinding media charge/load. Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs. They may be used for pulverizing and either wet or dry grinding ...

Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills. Equip yourself with the gold standard ...

Ball mill bearing Company. Chaoyang Runxing Heavy Machinery Manufacturing Plant was established in are famous China Ball mill bearing Factory and Ball mill bearing OEM .Main products are babbitt bearings, bearing bushings,plain bearings and Ball mill products cover construction machinery, heavy machinery, electric power ...

· This machine is a feed grinder and would be intended for grinding animal feed; definately not a coffee grinder. The auger in the bottom of the hopper is meant for crushing corn cobs into small enough pieces to be ground up by the plates. These machines have standard grinding plates just like all the other mills like the Letz, International, Bell, etc. As for the ball bearing.

grind gold miners mill small scale manual Mercury free small scale artisanal gold mining in Mozambique Artisanal and small scale gold mining accounts for a significant portion of the current mercury is then added to the ball mill and a miner manually grinds...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone ...

· From a bearing point of view, there are two bearings at the end of the shaft on the pinion and there are two bearings on either end of the ball mill. And obviously, the ball mill bearings are ...

· Tube mills are usually fed balls smaller than 2 in., whereas 4 or 5in. balls are more commonly used for ballmill grinding. A much higher grinding capacity is obtained in tube mills by using steel media instead of pebbles, but in making such a conversion serious consideration must be given to the ability of the steel shell to withstand the greater loading. Approximate ball loads can be ...

Laval Lab, the onestop specialist in Milling. For over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing. We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical ...

® mill linings are customdesigned for each grinding appliion with consideration given to available mill power, trunnion bearing loads, mill weight restrictions, grinding media charge volume and service life. Designed using most uptodate technologies and design tools to ensure an optimum system design and accurate liner fit.

Trunnion bearing housings for grinding mills FSDR .. K series Bearing types • Spherical roller bearings Bearing dimension series • 39, 48 and 49 Shaft diameter range • 825 to 1 460 mm Typical bearingshaft combinations • Stepped shaft with bearing on an unthreaded sleeve Seals • Labyrinth, Vring, PTFE strip Lubriion • Grease Materials • Grey cast iron • Spheroidal .

Compared to the pregrinding systems, including ball mills with high energy consumption and low efficiency, these cement mill roller presses consume less energy and produce lower noise. This roller press can improve the grinding capacity by 50 compared to ball mill systems and reduce the grinding system's power consumption by 3040% and 2030% of finished cement. The squeezed .

· Tube mills are usually fed balls smaller than 2 in., whereas 4 or 5in. balls are more commonly used for ballmill grinding. A much higher grinding capacity is obtained in tube mills by using steel media instead of pebbles, but in making such a conversion serious consideration must be given to the ability of the steel shell to withstand the greater loading. .

Trunnion bearing housings for grinding mills – FSDR..K series . SKF Cooper split units . Superprecision bearings . Principles of bearing selection and appliion . Angular contact ball bearings . Cylindrical roller bearings . Double direction angular contact thrust ball .

· Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system. There is a specific operating speed for most efficient grinding.

Cone Ball Mill Super Fine Grinding Mill JXSC Machine. Feb 09 2018 Introduction Cone Ball Mill is suitable for grinding all kinds of ore and other materials is widely used in mineral processing building materials and chemical industries ball mill mining can be divided into dry ball milling and wet milling According to different ore discharge methods it can be divided into grid type and overflow ...

Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only. SAG and AG Mills operate by lifting ore/grinding media and dropping it on the operating bed of the mill charge. High impacts from lifting ore and media promote impact breakage which is the primary mechanism for size reduction in the mill. Via the use of sophistied instruments ...

The Ball Mill Pulverizing and 3080 plant is involved in Grinding of Quartz and Feldspar Our Ball Mill does grinding of Fine Mesh in size ranging from 150350 Mesh The grain size of 010 mm is being produced in 3080 Mesh Grinding Plant Also we are producing Potassium Feldspar in size 60 and 80 as per the customer's sieving requirements

· All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum. The fragmentation of the material in that charge occurs through pressure ...